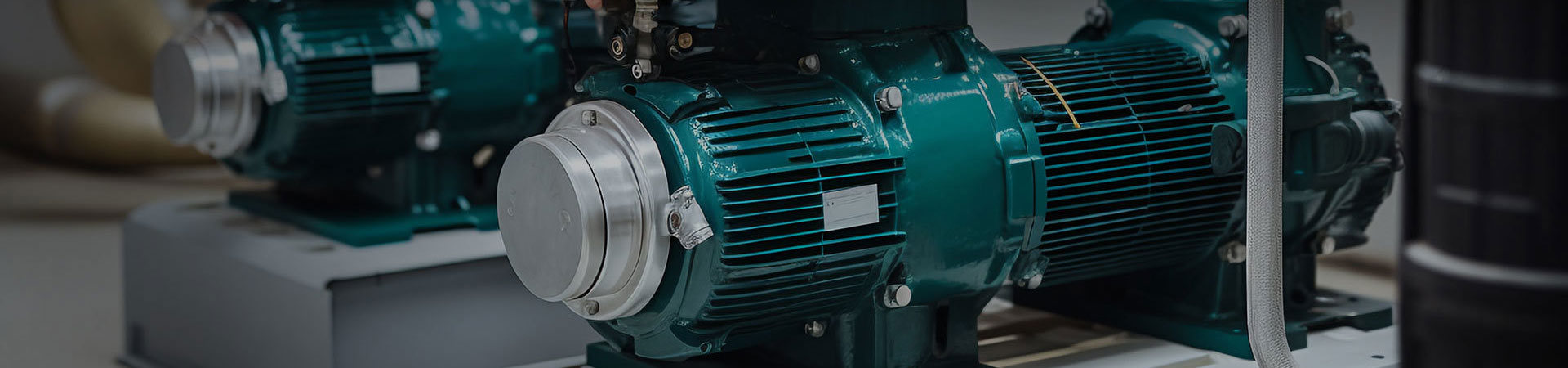

Product name:QBY Pneumatic Diaphragm Pump

Category:Other pumps

Release time:08-08-2024

Number of views:61

Product Introduction

QBY pneumatic diaphragm pump can not only pump flowing liquids, but also transport some media that are not easy to flow. It has many advantages over conveying machinery such as self-priming pumps, submersible pumps, shielded pumps, mud pumps, and impurity pumps.

1. No need for irrigation and water diversion, with a suction height of up to 7m, a lift of 70m, and an outlet pressure of ≥ 6kgf/cm2;

2. Spacious flow and good performance, allowing for a maximum particle diameter of up to 10mm. When pumping mud and impurities, there is minimal wear on the pump

3. The head and flow rate can be infinitely adjusted through the opening of the air valve (the air pressure can be adjusted between 1-7kgf/cm2);

4. The pump has no rotating parts and no shaft seal. The diaphragm completely separates the pumped medium from the moving parts and workpiece medium of the pump, and the conveyed medium will not leak outward. So when pumping toxic, easily reactive or corrosive media, it will not cause environmental pollution and endanger personal safety;

5. No need for electricity, safe and reliable to use in flammable and explosive places;

6. Can work submerged in a medium;

7. Easy to use, reliable in operation, with simple opening and closing of the gas valve for on-off operation. Even if the pump runs without medium for a long time or suddenly stops due to unexpected situations, it will not be damaged. Once overloaded, the pump will automatically stop, with self-protection performance. When the load returns to normal, it can automatically start and operate again;

8. The pump has a simple structure and few vulnerable parts. It is easy to install and maintain, and the medium transported by the pump does not come into contact with moving parts such as the valve and connecting rod. Unlike other types of pumps, the performance gradually decreases due to wear and tear of components such as rotors, pistons, gears, and blades;

9. Can transport viscous liquids (viscosity below 10000 centipoise);

10. This pump does not require oil lubrication, and even when idling, it has no impact on the pump, which is a major feature of this pump.

Main purpose

1. Pump peanut butter, kimchi, mashed potatoes, sausage, chocolate, hops, syrup, etc;

2. Pump paint, pigments, adhesives, binders, etc;

3. Pump various tiles, porcelain, bricks, and ceramic glaze slurry, etc;

4. Pump various abrasives, corrosives, and clean oil stains, etc;

5. Pump various highly toxic, flammable, and easily flammable liquids, etc;

6. Pump various types of sewage, cement grouting, and mortar, etc;

7. Pump various strong acids, strong alkalis, strong corrosive liquids, etc;

8. As a front-end pressure feeding device for various solid-liquid separation equipment.

- Previous:

- Next:CYBW series marine air pump